Corrosion resistance of diamond-like film deposited on inner wall of steel pipe

Diamond-like carbon (DLC) coating has the excellent properties of high wear resistance, very low friction coefficient and high corrosion resistance. Due to these excellent properties, DLC coatings have attracted a lot of attention in the oil and gas, semiconductor, medical and automotive industries.

In the oil and gas industry, DLC coatings are particularly useful for improving the tribological and corrosion properties of pipe inner surfaces, pipe joints, drilling RIGS and boreholes.

Diamond carbon (DLC) coating has high wear resistance

1. Film section diagram

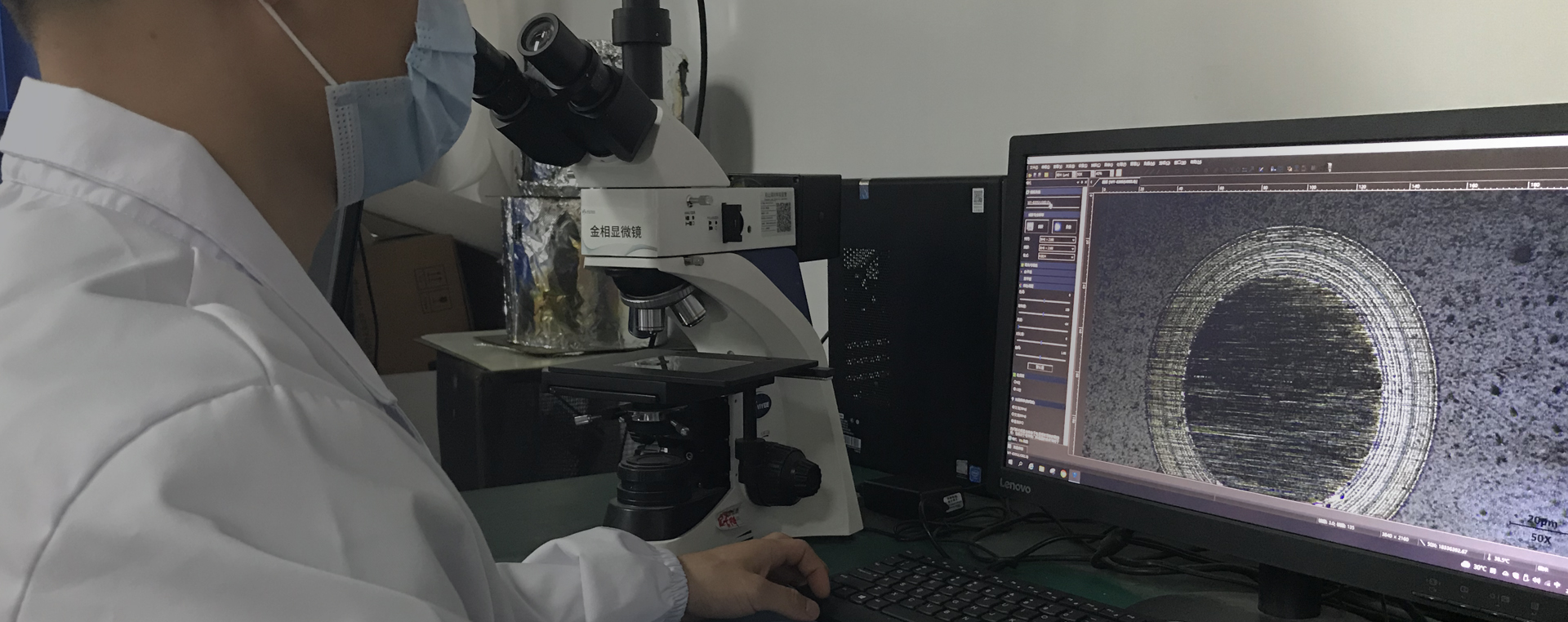

Figure 1 shows the SEM section of the DLC coating. In the image, the brightest area is the steel substrate, followed by the silicon precursor deposition area and the darkest hydrocarbon precursor deposition area, while the middle brightness area is the mixed silicon and hydrocarbon precursor deposition area.

Scanning electron microscopic section of DLC coating

Figure 1: SEM section of 40 micron membrane layer

2. Corrosion resistance test of film

The corrosion resistance of the film was tested by exposure to 15% hydrochloric acid at room temperature, 70C and 10% sodium chloride solution for 24 hours. Figure 2(A and B) shows an optical micrograph of the sample after hydrochloric acid and saline solution, showing that the DLC-SI coating provides good protection for the substrate. This is because the DLC is chemically inert and can act as a physical barrier between the substrate and the corrosive environment as long as the coating is free of defects.

Corrosion resistance test of film

Figure 2(A and B) : Optical micrograph of sample after hydrochloric acid and saline solution

Another corrosion test is an acidified autoclave according to NACE TM0185 standard. This is a three-phase test (aqueous phase - distilled water, organic phase - xylene, gas phase -1% hydrogen sulfide, 85% carbon dioxide, 14% methane) performed under high pressure. Figure 3 shows the results of the test on the inlet, middle, and outlet samples. Note that the coating passed the NACE standard test without damage or blistering.

Corrosion test

Figure 3: Sample images at inlet, middle, and outlet

summary

The experimental results show that DLC coating provides good corrosion protection for pipeline matrix. The application of DLC coating technology in oil and gas industries is expected to improve the corrosion performance of pump barrels, downhole tools, pipelines, drilling fixtures and other components.

18922924269

18922924269